Ever wondered how machines operate? It's pretty fascinating! Single phase motors are a unique form of motor that comprises many machines you see each day. You may have come across them in things like fans, washing machines and dryers air conditioners, even car engines. The only task of these motors: convert electrical energy, received from power outlets into mechanical. That is the energy that gets machines going and doing their job.

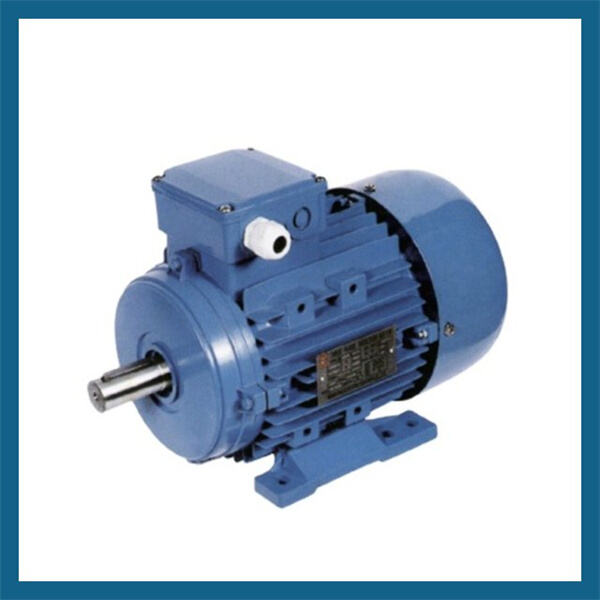

The single phase motors have two main parts that are important which includes: it has a stator and rotor part. For three-phase alternators, the stator is stationary and does not turn with a wire winding while the rotor slewing about as it also holds exclusive magnets. A magnetic field when a current pass though the motor. This magnetic field is an invisible force that drives the rotor to spin creating mechanical energy, resulting into power in use by the machinery.

The thing is that the single phase motors can offer a large number of benefits. The first reason is that they can be found in stores, are very easy to use and most importantly the cost of these at one usually does not exceed other types. They are energy-efficient appliances since they consume less power-effective than traditional models) It, in turn, saves on electricity bills for both people and businesses.

But the single phase motors have their own disadvantages as well. They are not the torque beasts that some other motors can be (the type you would use to create a really strong gear reduction train for example) so they may have trouble handling very heavy duty applications. Also, single phase motors requires a extra starting devices like capacitor or centrifugal switch to make them start. Without this start-a-motor may not work, or even run poorly.

Without a doubt, you can not ignore your due diligence when it comes to selecting the proper single phase motor. You need to choose wisely, as you want one that will suit your needs. When choosing a motor, you want to consider power output (horsepower), how fast it can run and most importantly the efficiency.

It is also extremely important that you understand how to properly care for your single phase motors so they will last and not have any kind of repair work done to them at all. This will need to be done and checked every so often as part of routine maintenance. It is also necessary that the moving parts are lubricated and if any of them seem to be wearing out or in worse condition, you should replace them immediately.

If you see any problems with the single phase motor as it is getting too hot, vibrating or making strange noises then make sure to troubleshoot on time. Such issues are a sign of anything related to the parts in the motor (bearings, wiring etc., ) itself. By catching and repairing these issues early on, you can eliminate problems later down the line ensuring your motor runs as smooth as possible.

WETONG utilizes single phase motor low-cost labor and uses a high-efficiency streamlined management system This strategic approach allows us to minimize production expenses without compromising on quality We give our customers the most competitive prices in the market and guarantee exceptional value and affordable prices

we're dedicated to provide our customers with a an extensive single phase motor service we maintain a inventory of most of our pumps to ensure prompt delivery technical consultations repair of components as well as other professional services are a part of our after-sales services the robust support system guarantees that our clients receive continuous and reliable assistance which reinforces our dedication to be a trusted one-stop-shop solution provider

WETONG 30 years experience industry and leader when comes expert pumping solutions we've adopted most up-to-date technology pumping enhance know-how ensure some parts pumps interchangeable renowned international brands guarantee quality compatibility commitment quality single phase motor reliable partner world pumps

the WETONG single phase motor consists of professionals with years of knowledge of the global market we are fully aware of the stringent requirements of our customers and adhere to strict production guidelines to ensure that we meet the requirements of these standards we make sure that every pump is subject to strict quality control processes to ensure that they meet the highest standards this is our dedication to delivering top-quality products